A modern genset is a backup power unit, just like other traditional generators, but with minimal noise. They are designed with advanced sound-dampening devices and noise-reduction technologies like acoustic enclosure to ensure a quiet operation. Perfect for noise-sensitive environments where loud generators can affect the smooth functioning of businesses. In short, on top of offering reliable power solutions, silent gensets are preferred for their ability to deliver power without fluctuations and disturbing the surrounding environment.

TMTL-Eicher Gensets

TMTL-Eicher Silent Gensets are manufactured by TMTL Engines Division. TMTL – TAFE Motors And Tractors Limited is a wholly subsidiary of TAFE, that came into existence when TAFE acquired the tractors, gears, transmission and engines business from Eicher Motors Limited in 2005. TMTL-Eicher Silent Gensets are designed with state-of-the-art acoustic enclosures and vibration isolation systems to ensure minimal noise. For people looking for the best generator in India, TMTL silent genset is an excellent choice. TMTL manufactures the most powerful gensets in their class, starting from generator 5 kVA to generator 125 kVA.

Features of TMTL Silent Gensets

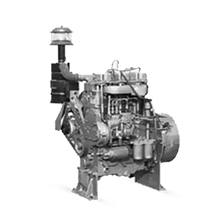

TMTL Silent Gensets come with advanced technology and features, making them a preferred choice for consumers and businesses. From advanced engine technology and unmatched fuel efficiency to a plethora of applications, TMTL silent genset is the superior choice for residential, commercial, or industrial applications. These silent gensets are powered by advanced and robust Eicher engines renowned for their fuel efficiency and reliability. The engines incorporate advanced technologies to optimise fuel consumption and reduce emissions.

One of the standout features of TMTL silent gensets is their exceptional acoustic enclosures. As mentioned earlier, these enclosures are designed to significantly reduce noise levels even under full load, making these gensets suitable for use in noise-sensitive environments like hospitals, schools & resorts. TMTL Silent Gensets uses a Closed Rolled Closed Annealed (CRCA) sheet for the acoustic enclosure to ensure longer life. The silencer is placed inside the canopy for protection from harsh weather, ensuring longer life and better aesthetics as well.

TMTL Silent Gensets use 40 mm Polyurethane Foam (PU) for generators from 5 to 62.5 kVA and 50 mm PU Foam for generators from 82.5 to 125 kVA. The PU Foam in the gensets is the thickest in its class, securing low noise and vibration levels. Super-silent options are also available. This feature ensures smoother operation and extends the life of the genset components by minimising wear and tear.

The compact size not only saves space but also makes it suitable for rooftop installations. For ease of maintenance, it comes with large doors on either side and a drain for lube oil and the fuel tank. On top of all this, TMTL Silent Gensets have a state-of-the-art powder-coating plant for advanced long-life weather protection. The dual fuel lock, S-bend fuel pipe, and stainless steel fuel strainer make these gensets theft-proof.

TMTL Silent Gensets incorporate a comprehensive array of safety features to ensure the safe and reliable operation of the generators. The unitary front and back panel, canopy with internal bolting, usage of Stainless Steel (SS) hinges with SS studs, and SS slam locks with barrel and padlock arrangements are just a few of the safety measures followed by TMTL to bring in for the highest degree of safety and safeguard both the equipment and its users.

How To Maintain TMTL Silent Gensets?

The “running in period” of a new engine, i.e. the first 50 hours, is extremely crucial for the engine’s life. And, that’s why it is important to follow the below instructions during the first 50 hours.

- Start the engine and run it at ‘NO’ load for the first 3 to 5 minutes to warm up the engine oil.

- Observe and monitor the gauges and indicators of the control panel.

- Gradually apply load on the Diesel Generator (60 to 80% of the specified full load).

- Avoid any overloading on the engine / Diesel Generator at any point.

- After the first 50 hrs of engine, strictly follow the service schedule as specified by the manufacturer.

- In case of any abnormal noise, please stop the engine immediately and contact the nearest authorised service dealer or call our trained service team at 1860 425 8685.

Another important point to note, especially during the first 50 hours, is that prolonged operation at light loads during the early life of the engine can cause lubricating oil to enter into the exhaust system. A minimum 60% load should be applied 3 to 5 minutes after the engine starts running. It will be better for the engine if the load is applied as soon as possible, i.e., right after the oil warms up.

Applications And Industries

TMTL Engines Division is known to offer custom-built products and services to cater to a wide range of institutional and retail customers ranging from banking and finance, rental agents, commercial, construction and real estate, hospitality, information technology, government and public sector, small and medium enterprises, petrol pumps, educational institutes, residential and hospitals etc., and has an existing base of over 10 lakh happy customers.

TMTL Engines Division is rapidly emerging as one of India’s leading engine manufacturers. It holds a strong market presence in the Telecom sector, where quality and timely service are crucial, and is supported by an extensive and growing service network. TMTL Engines Division’s flagship product, the 125 kVA genset, is one of the most technologically advanced gensets in India with an indigenously developed CRDI engine and Isochronous Governing.

TMTL has always been keen on customer satisfaction and that’s why there will be a single point of contact throughout the process. TMTL also has a pan India service network and assures round-the-clock assistance. If you have any queries, you can feel free to connect with our highly qualified and trained service team at 1860 425 8685.